What are smoke and heat extraction systems (SHEVS)?

Smoke and heat extraction systems (SHEVS) are an indispensable element of preventive fire protection, especially in industrial environments. These systems effectively remove smoke and heat from buildings in case of fire, saving not only human lives but also property. The rapid removal of smoke improves visibility in escape routes and makes firefighting considerably easier.

Protection goals and their fulfilment through smoke and heat extraction systems

Protection of people

- Smoke-free escape and rescue routes

- Support of self- and third party rescue

- Localization of the fire source

Protection of the environment

- Limitation of environmental damage

- Reduction of polluntant release

- Localization of the fire source

Protection off property

- Thermal reliefe of the building

- Securing building values and maschines

- Preservation of the building fabric

Functionality of SHEV systems

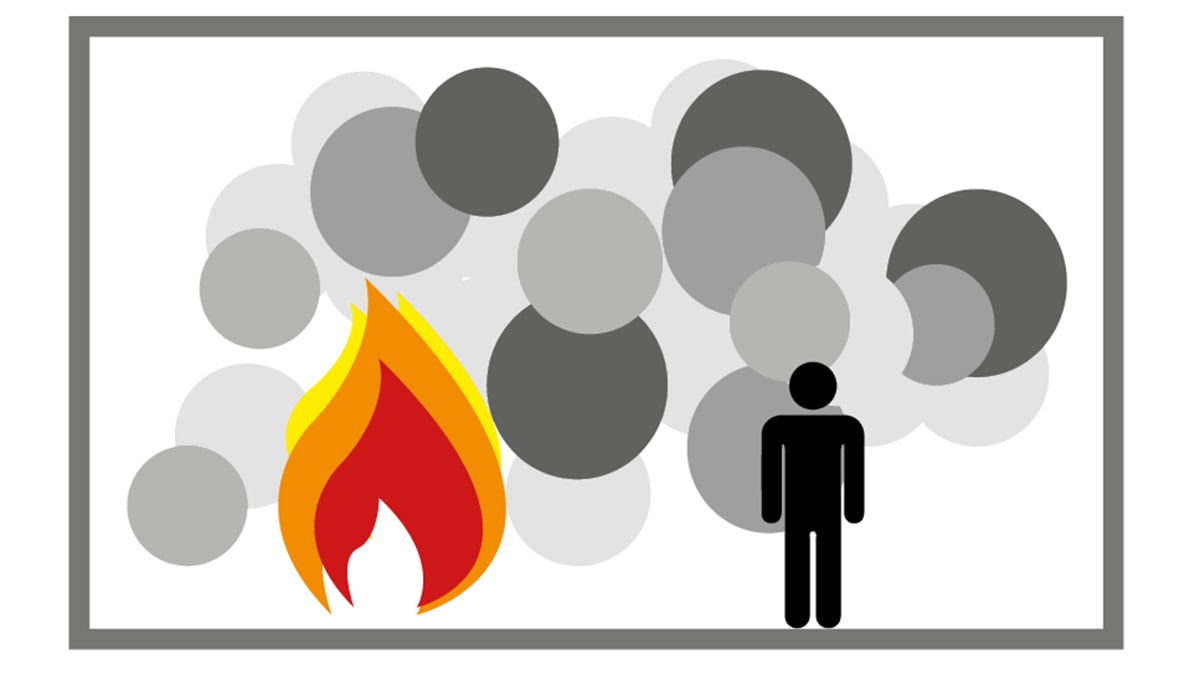

What happens to the smoke without SHEVS?

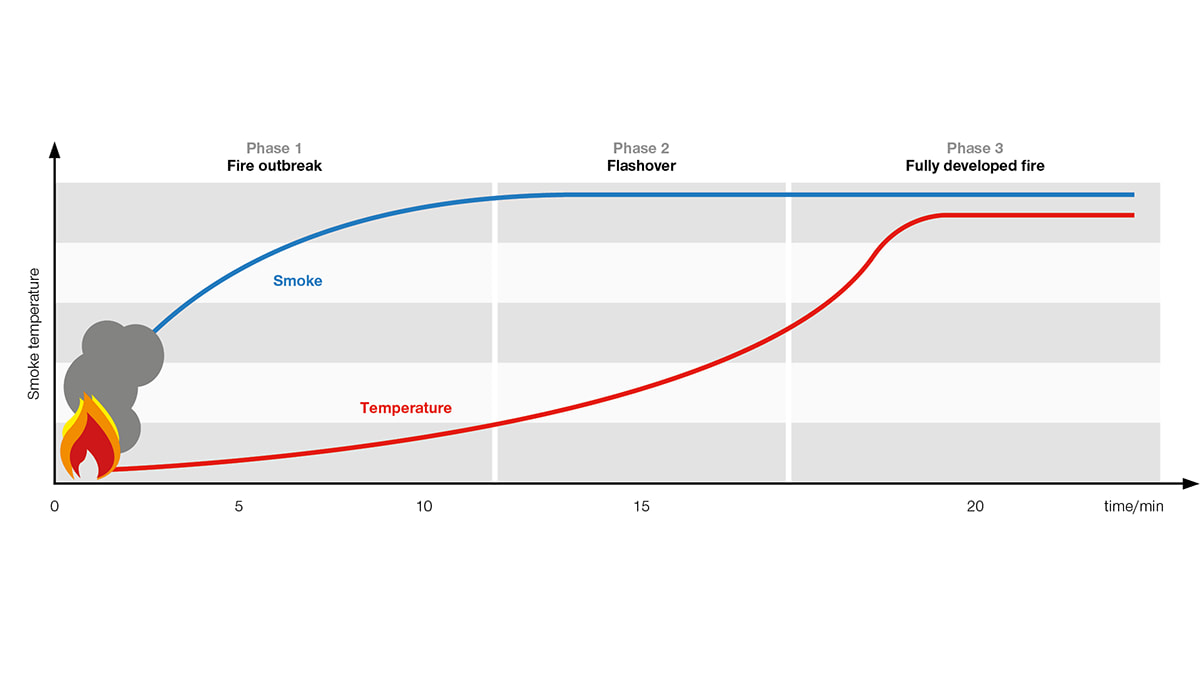

Without a smoke and heat extraction system (SHEV), smoke spreads throughout the building in an uncontrolled way. Due to thermal buoyancy, the smoke rises upwards and quickly fills the upper areas of rooms and corridors. This leads to heavy smoke build-up, which makes escape routes impassable and significantly impairs visibility. In addition, the heat build-up is increased by the trapped smoke, which can endanger the structure of the building and make firefighting more difficult.

If the heat is not extracted, there is a risk of flashover at approx. 600°C. This means that the gases suddenly ignite in the entire room and lead to a full fire.

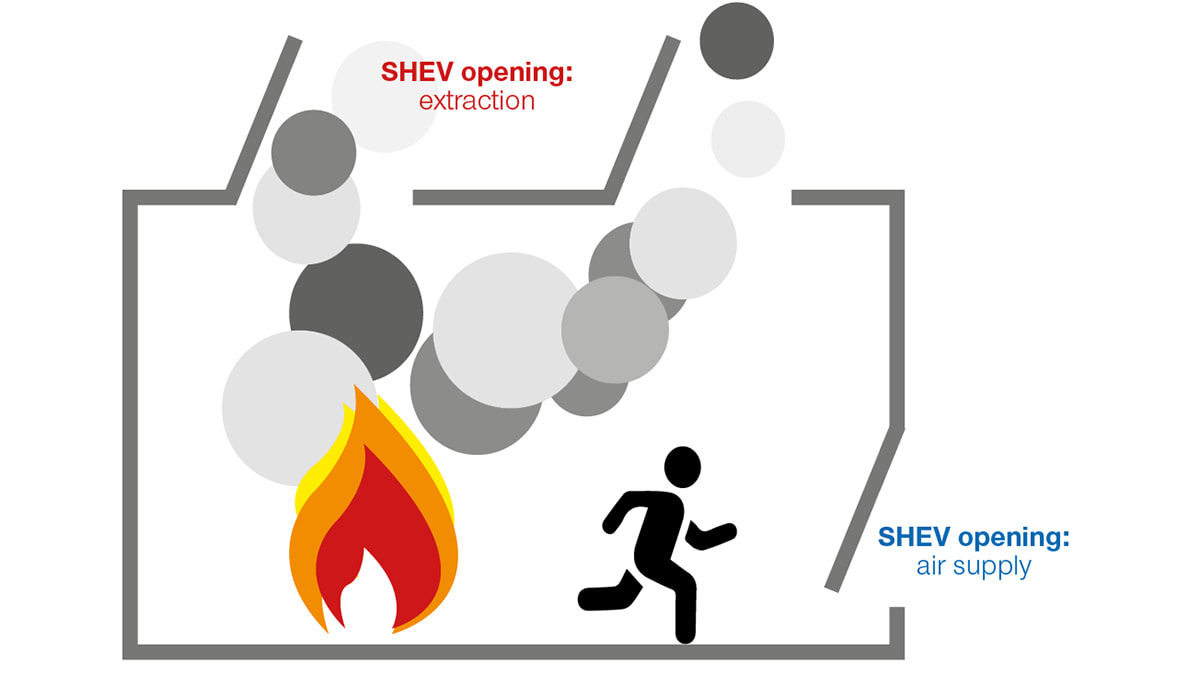

Physical principle of thermal buoyancy

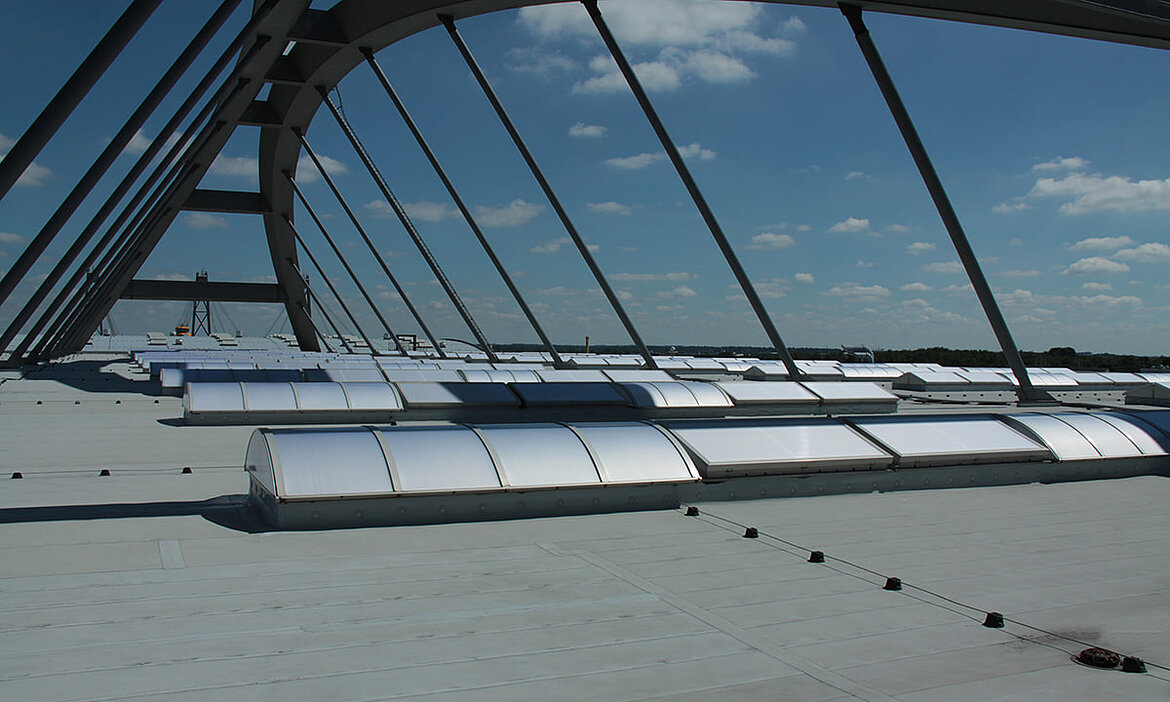

The functionality of SHEV systems is based on the physical principle of thermal buoyancy. Warm air rises upwards and escapes through specially designed openings in the roof or façade. These openings allow the dangerous fire smoke to be extracted to the outside, keeping the lower areas of a building smoke-free. This facilitates evacuation and enables the fire brigade to localise and fight the source of the fire faster.

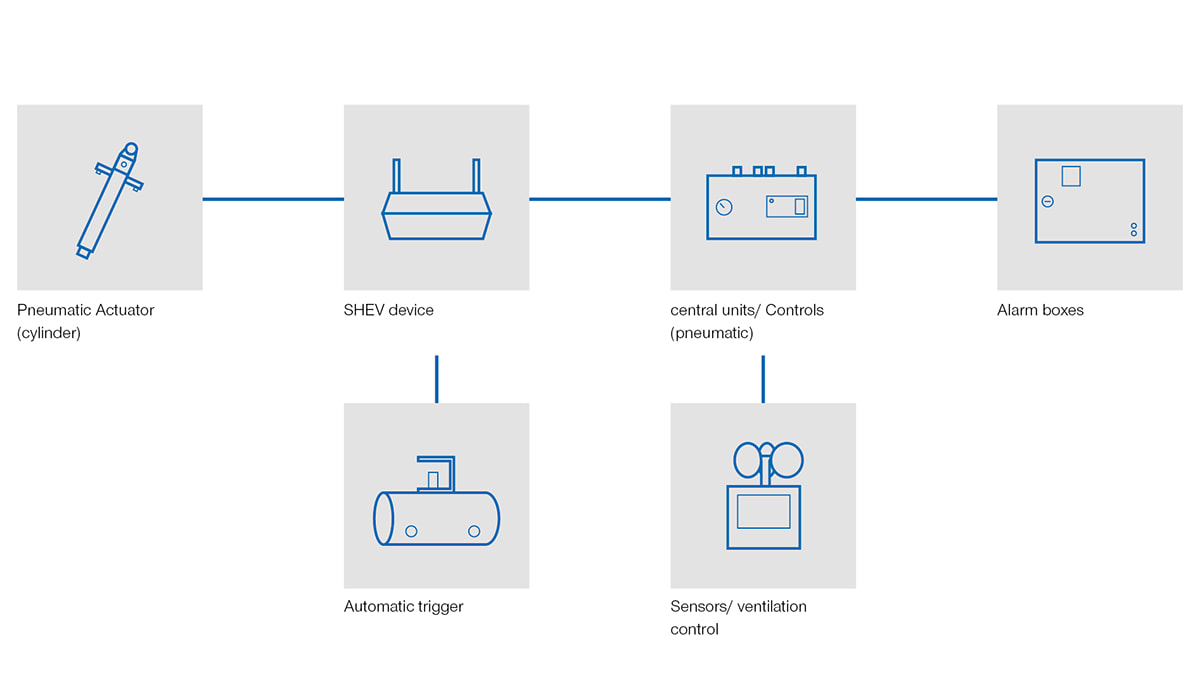

Components of a SHEV system

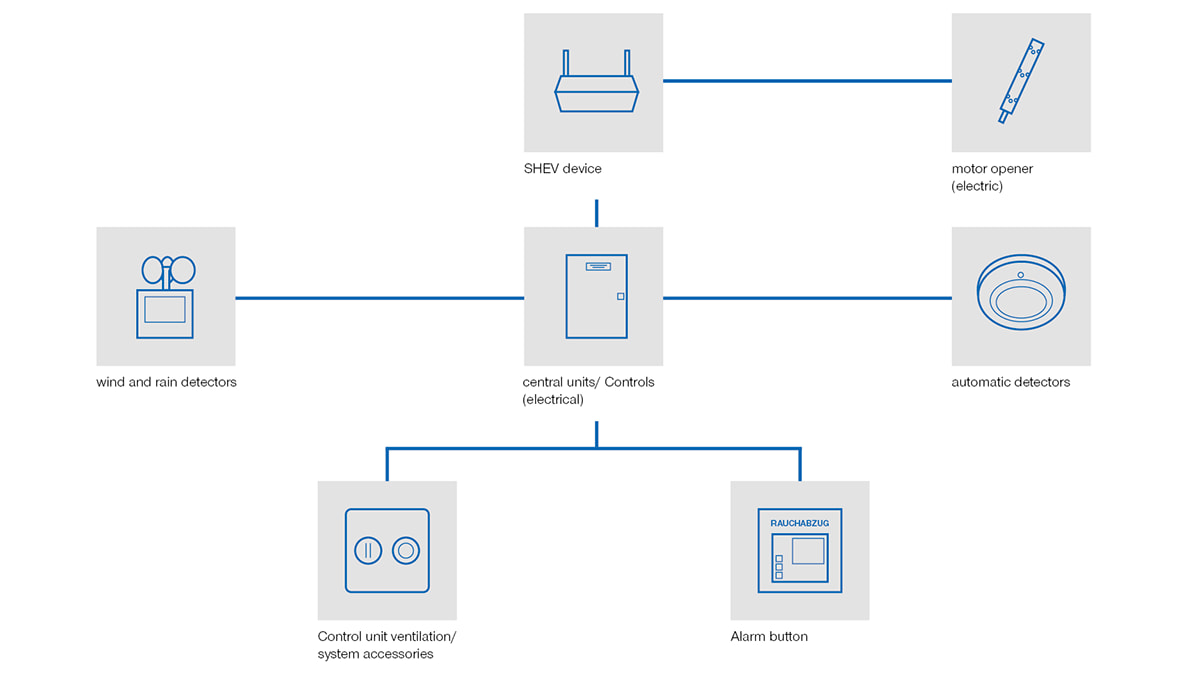

A typical SHEV system in industry today often fulfils a dual function for natural ventilation and for smoke and heat extraction and can be operated either electrically or pneumatically. The SHEV function always takes precedence over the ventilation function, which is deactivated in case of fire. In case of fire, they are triggered automatically or manually. Consisting of several components that work together it will effectively extract smoke and heat in case of fire:

- Smoke and heat extraction devices (SHEV): These elements open in case of fire and allow smoke to be extracted.

- Triggering and operating elements: These include manual detectors and external alarm devices that activate the SHEVS.

- Energy supply: Emergency power batteries and compressed gas storage ensure function even in case of power failure.

- Supply air supply: Openings that allow fresh air to flow in to support thermal buoyancy.

Advantages of smoke and heat extraction systems

SHEV systems offer numerous advantages that make them an indispensable element of fire protection:

- Securing escape routes: Smoke-free escape routes enable safe evacuation.

- Effective firefighting: Improve visibility and accessibility for the fire brigade.

- Protect the building structure: Prevent dangerous heat build-up by extracting smoke.

Definition of SHEV systems

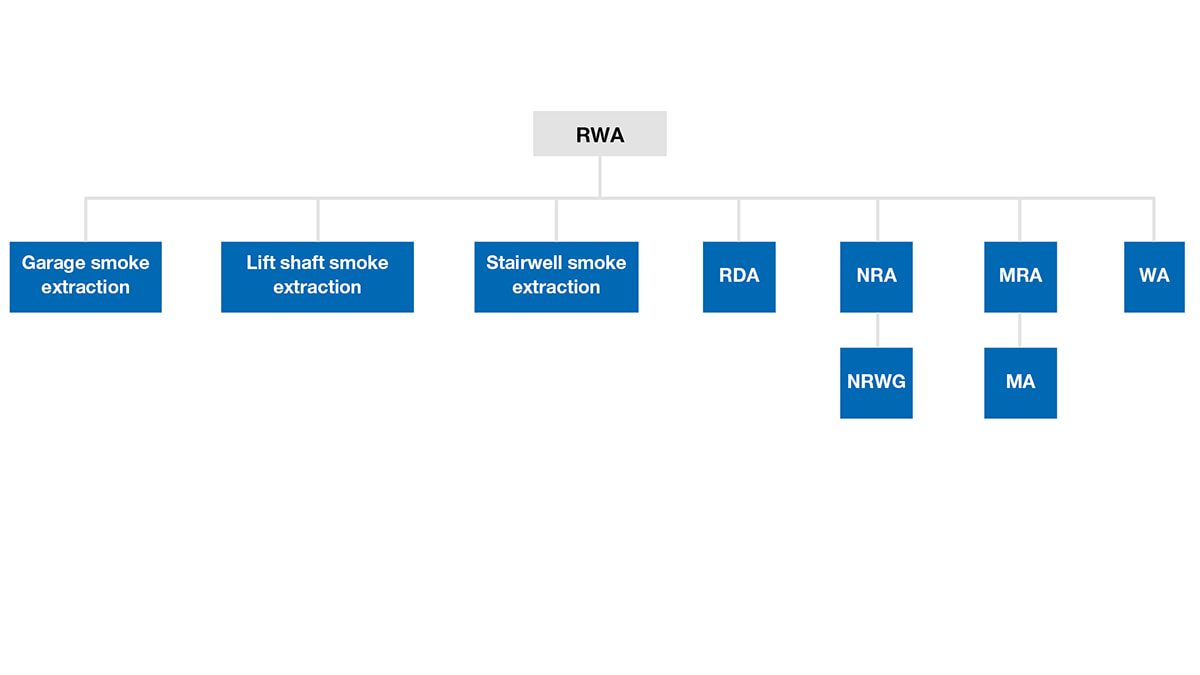

Different types of smoke and heat extraction systems

Natural smoke extraction system (NRA)

An NRA provides open areas in the upper third of the room through which smoke is extracted as a result of thermal buoyancy. It only works for hot smoke, but is more effective and less expensive than an MRA. The NRA also functions as a heat extractor and is characterised by the principle of thermal buoyancy.

Mechanical smoke extraction system (MRA)

An MRA uses motorised drives such as fans to extract smoke. It requires a reliable power supply throughout the entire operation, while NRAs only require initial energy to open the surfaces. MRAs are particularly suitable for lower storeys and can also extract cold smoke.

Stairwell smoke extraction

Smoke layering to keep escape and fire extinguishing routes smoke-free is not possible in stairwells, as the smoke rises through the entire stairwell. Fire load-free stairwells and self-closing, smoke-tight doors are therefore mandatory. Stairwell smoke extraction is required from a height of 13 metres or five storeys and for internal stairwells in accordance with state building regulations. The fire brigade uses mobile fans at the entrance door to clear the smoke.

Natural smoke and heat exhaust ventilator (NRWG)

NRWG is a part of a smoke extraction system. It refers to the individual product that creates an opening (measured as Aa (EN) or Aw value (DIN) in square metres of smoke extraction area), such as the double flap ventilator in the roof or the louvre window in the wall. These devices utilise thermal buoyancy to extract smoke.

Heat extraction (WA)

The WA is a wall or roof surface that automatically releases an opening at a certain temperature, for example by melting thermoplastic roof light elements. This vent removes accumulated heat and smoke, but opens later than an NRA and is therefore not suitable as a natural smoke extraction system.

Smoke differential pressure systems (RDA)

Smoke differential pressure systems prevent smoke from entering escape routes by means of overpressure. Fans and flaps ensure a slight overpressure in the rooms to be protected so that smoke from a corridor cannot enter the stairwell, even if the doors in between are opened.

Garage smoke extraction

A garage smoke extraction system is an individually planned and designed smoke displacement and smoke extraction system. It supports self-rescue and rescue, fire-fighting and property protection. The selection of a smoke extraction system for garages depends on the area and height of the garage room and whether the garage is above or below ground. In underground garages, thrust fans force the smoke into certain areas from which it is extracted, as smoke layering is not possible due to the low ceiling height.

Lift shaft smoke extraction

Lift shaft smoke extraction using SHEV systems fulfils two legal requirements: smoke extraction in case of fire and ventilation when required. Smoke detectors and vents are installed at the top of the lift shaft for this purpose. In case of fire, these are triggered and direct the smoke upwards out of the shaft. The main goal is to prevent the transfer of smoke from one floor to another via the lift shaft.

Building regulations in Germany

In Germany, the requirements for SHEV systems are laid down in the building regulations. Each federal state has its own building regulations and special building regulations that must be complied with. The components and systems used must comply with European and national standards (DIN EN 12101 and DIN 18232) and must be CE-labelled.

Requirements and tests

The standards DIN EN 12101 and DIN 18232 stipulate that SHEV systems must undergo regular testing and maintenance. These tests include:

- Determination of the aerodynamically effective opening area

- Reliability tes

- Functional test under load

- Functional test at low ambient temperature

- Stability test under wind load

- Heat resistance test

- Flammability test of the materials

Planung, Installation und Wartung von RWA-Systemen

Project planning and dimensioning

Installation and commissioning

Regular maintenance

Careful planning is crucial for the effectiveness of SHEV systems. Project planning includes the calculation of the necessary exhaust and supply air openings and the selection of suitable components. Here, the specific requirements of the building must be taken into account in order to ensure optimum function.

SHEV systems should be installed by certified specialist companies. After installation, commissioning takes place, during which all components are tested for functionality and are adjusted.

Regular maintenance is essential to ensure the proper functioning of a SHEV system. This includes checking all mechanical and electrical components and testing the function of the trigger mechanisms.

Advantages of SHEV systems in new and existing buildings

New buildings

In new buildings, all fire protection requirements can be taken into account right from the start. This means that structural measures and systems can be integrated optimally to ensure a high level of safety. Modern technologies and materials improve the protection of life, health and physical assets.

Existing buildings

In existing buildings, existing building structures and materials must be taken into account, which can present additional challenges. Retrofitting and adaptations are necessary to align fire protection with current standards and regulations. roda offers customised solutions for the renovation and modernisation of existing buildings.

roda system solutions for smoke and heat extraction and ventilation

Conclusion

Smoke and heat extraction systems are indispensable for fire protection in buildings. They offer comprehensive protection for people, property and the environment. A well-planned and well-maintained SHEV system is a decisive factor for safety and can save lives in an emergency. Rely on the expertise of roda Licht- und Lufttechnik GmbH for innovative and durable solutions.

Further information and contact

For more information about our smoke and heat extraction systems, visit our website or contact us directly. Our experts are always available to answer your questions and support you with your projects.

Contact

We are available for you